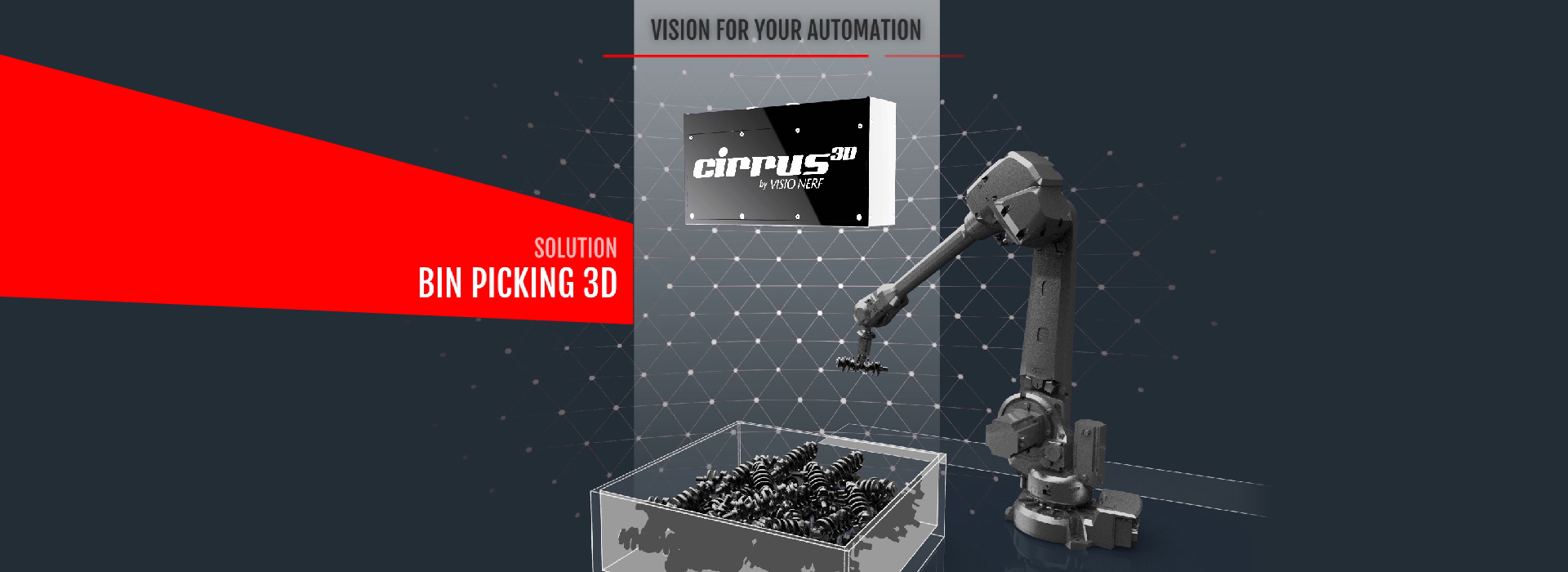

Machine vision: Bin picking, 3D vision

The robotic guidance by 3D vision is becoming a key element of the Industry 4.0 for the industrial process automation. Picking parts applications for machine tool tending, called bin picking are crucial points to automate. 3D vision sensors are able to give eyes to the robots to make them smarter.

Our machine vision solutions

3D Vision :

More and more applications related tothe automation of production tools can not be solved anymore thanks to 2D vision. VISIO NERF is specialized with success for more than 10 years now on the 3D vision technology. VISIO NERF offers to its customers a range of innovative, patended solutions for a maximized RoI.

Bin Picking :

The automatic picking of parts to load machine tools, to place parts in cardboard boxes, racks, on a stand, for pick and place applications are all projects achievable with 3D vision driving a robot. The 3D sensor will scan the working scene in order to chose the right part to pick in the box for bin picking operation. The designated part can be picked without any collision with the working volume. The cycle time of a bin picking application is really fast and can reach few seconds. The comparison between the CAD model of the part and the scan obtained with the 3D sensor, cirrus3D and its patented software, allows a fast and accurate analysis of the bin picking scene.

Robotic guidance :

Cost-effective automation of the finishing or machining of mechanical parts is a major aspect for industries. Cost-effective automation of assembly lines is also a key project in the industry 4.0. 3D Vision allows scanning parts and to make an accurate localization locally on the part guiding the robot in its trajectories for these precision operations.

Inspection :

Quality of delivered product is an important question in industrial production, the tools developed around the 3D vision allow in line quality inspection in order to detect for instance: lack of material, surplus of material, dimensional check, cavity check… eyesberg3D, the patented software from VISIO NERF offers the measurement results exploitation in the form of a positioning in a scale of values where the part is located: critical / acceptable / part OK and this over the entire tolerance range.

Be contacted

by our team

* Required

They have chosen VISIO NERF

Machine Vision : applications by business

Automotive

Bin picking of raw parts or finished parts for machine tool loading. Robotic guidance by 3D vision is as performing for mechanical parts ( cranckshaft, breaking disk, steering etc) as skiny parts such as body parts.

Foundry

As for the automotive, 3D vision sensors are used for robotic guidance for precision operations ( deburring, machining etc) but also for the picking of parts in bulk, bin picking for machine tool tending. 3D cameras allow also in line inspection for quality inspection.

Forge

Parts picking out of ovens, parts picking on a conveyor, bin picking of raw parts are all applications which can be done thanks to 3D vision.

Other industries

Collaboration between robot and vision is necessary for the picking of parts for pick and place or bin picking applications in industry.