Customer

cases

Leakproof thanks to the Cirrus 3D camera: A success story for Inficon

Inficon | Industry

Inficon is a leading global provider of innovative instrumentation, technology and software that are essential for gas leak detection in air conditioning / refrigeration

How Visionerf helped Pattyn with their Vision challenges

Pattyn France | Machine manufacturing

Pattyn France is part of the Pattyn Group, a group focusing on bag-in-box packaging solutions. The French chapter, based in Savignac, primarily focusses on providing pack

Sorting parts on a conveyor

Stellantis | Automotive, Industry

Our customer, the Sept-Fons site of the STELLANTIS group - a foundry specializing in the manufacture of cast iron automotive parts such as cylinder housings

Bin picking in hidden time

Renault | Automotive, Industry

Renault's Cleon plant puts its trust in Cirrus3D technology. A factory serving the Renault-Nissan Alliance, Cléon has 35 customer sites worldwide.

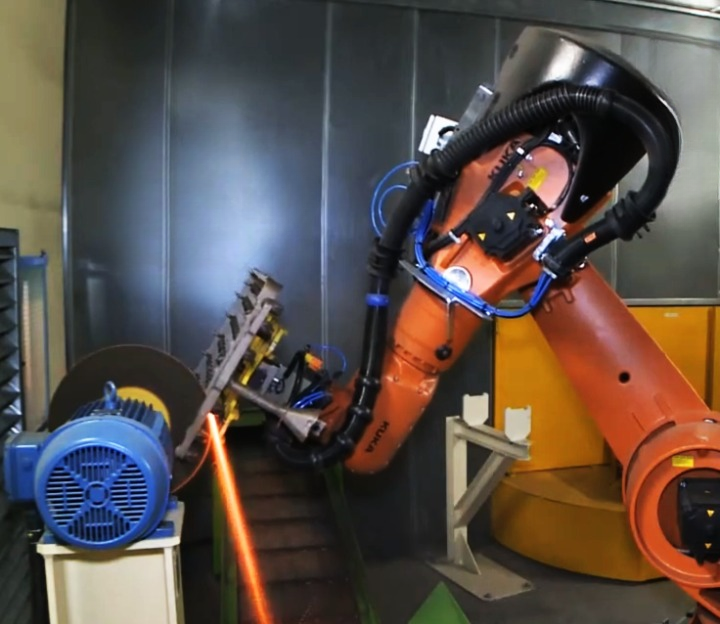

Robot-guided finishing

Cronite | Industry

The part is loaded into the cell via a turntable without mechanical referencing. It is then scanned and localized using a 3D scanner.