Awareness is Power

"Mieux voir, mieux connaitre vos produits, pour mieux maitriser votre process". Fabricant français de matériel de vision depuis plus de 30 ans, nous avons concentré notre savoir-faire dans le Cirrus3D, notre capteur 3D haut de gamme. Que vous soyez fabricant de machines, intégrateur robot ou vision, ou client final, nous avons sûrement le produit qu'il vous faut. Et si nous ne l'avons pas encore, nous pouvons l'inventer pour vous!

Découvrez nos Caméras 3D

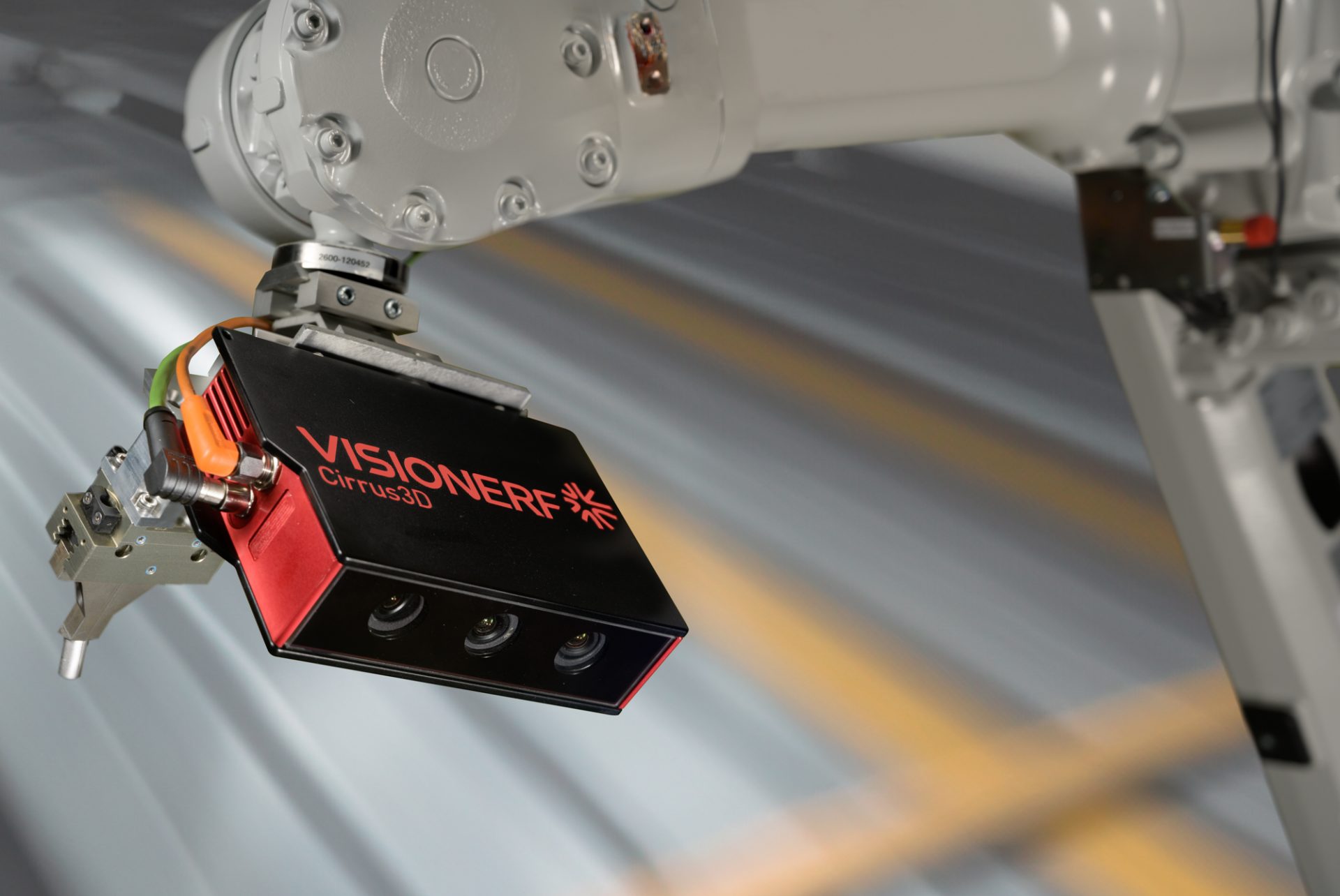

Cirrus3D

Nous avons la plus large gamme du marché de capteurs 3D: que vous ayez besoin de scanner des pièces petites ou grandes, fixes ou en défilement sur convoyeur, avec un capteur fixe ou monté sur robot, pour faire du contrôle qualité ou du pilotage de robot, vous trouverez forcément le modèle qui vous convient. Dédiés à un usage industriel, les Cirrus3D sont insensibles à l’environnement, aux poussières, aux saletés ou aux variations de luminosité et ceci afin de garantir une fiabilité et une robustesse de vos installations sans équivalent. Avec les Cirrus3D, inutile d'être un expert vision pour faire de la vision: pas de réglage de caméra, de netteté, d'éclairage, pas de calibration à faire. Tout ces réglages sont faits par nous, le capteur est prêt à l'emploi pour fournir des points 3D précis et calibrés.

En savoir plus

Nos

applications

Nos systèmes de vision industrielle sont aptes à mener à bien une multitude d'applications. Que ce soit la localisation facile et rapide de vos pièces brutes ou finies, l’automatisation d’opérations de précision sur des produits ayant une forme ou un positionnement inconnus, la réalisation d'un dévracage, l'identification d'une pièce ou le contrôle de la conformité de pièces de production, la gamme Cirrus3D vous apportera un excellent retour sur investissement.

adapté à

VOS

BESOINS

Nous vous accompagnons au bout de vos projets et co-développons à vos côtés un produit ou une solution qui conviendra parfaitement à vos besoins. Comptez sur nous pour vous fournir un capteur adapté à votre installation et qui s'intègre au mieux à votre solution déjà existante ou bien une customisation de notre offre pour un produit unique qui vous ressemble.

Témoignages

de nos clients