Cirrus3D

Linear

The Cirrus3D linear range is designed to scan parts on a conveyor. They can also be mounted on a linear axis to scan very big parts.

Due to its unique conveyor calibration method, it is much easier to use and setup than alternate solutions with laser triangulation. This method enables the Cirrus3D to learn the conveyor axis, the conveyor plane, and the encoder resolution. it takes only a few minutes. After this calibration, the Cirrus3D send to the software 3d points profiles as if it was perfectly placed on a plane perpendicular to the conveyor axis. All angles offset are compensated, enabling a simple and low cost fixed bracket to hold the Cirrus3D.

Acquisition speed

up to 1000 3D profiles/s

Calibration

Factory

Communication interface

Ethernet TCP/IP and GigE/Genicam

Case material

Aluminum

Connectors

Power supply and inputs/

outputs, Ethernet M12

outputs, Ethernet M12

Power supply

24V CC 2A max

Light source

Blue laser with selectable class 2 or 3R

Operating temperature

0°C...50°C

Compact, robust and lightweight

Sealed industrial connectors

power and Ethernet M12

Adaptative cooling

For better thermal stability

High-performance processor

Raw images processing fully integrated

cmos sensor

5Mpixels for each camera for high resolution

Easy to setup

Unique conveyor calibration method for easy and low cost setup

Resistant to dust and dirt

Compatible with hostile environments (IP65 standard)

Working volumes:

The widest range available on the market

| Cirrus3D model | Cirrus3D C 100 | Cirrus3D C/R 300 | Cirrus3D C500 | Cirrus3D C1000 | Cirrus3D C1500 |

|---|---|---|---|---|---|

|

Minimum working distance (mm)

|

150 | 410 | 630 | 1280 | 1850 |

|

Visible width at minimum distance

|

120 | 330 | 500 | 1000 | 1500 |

|

Resolution at minimum distance

|

30µm | 100µm |

150µm |

350µm | 560µm |

|

Maximum working distance

|

185 | 580 | 1000 | 3000 | 4000 |

|

Visible width at maximum distance

|

150 | 460 | 750 | 2200 | 3000 |

|

Sensor dimensions (WxHxD)

|

195x53x131 |

269x53x131 |

389x53X131 | 599x53x131 | 749x53x131 |

|

Sensor weight (Kg)

|

1.9 | 2,3 | 3,30 | 5,00 | 6,30 |

All dimensions are in mm, unless otherwise noted.

*For a single 3D point without averaging or interpolation. Part localization accuracy is up to 10 times better than resolution, but depends on discrepancies between the CAD file and the actual part. It depends also on the software used for cloud of points analysis.

Cirrus3D C/R 100

150

120 - 150

Cirrus3D C/R 300

410

330 - 460

Cirrus3D C500

630

500 - 750

Cirrus3D C1000

1280

1000 - 2200

Cirrus3D C1500

1850

1500 - 3000

Discover our solutions

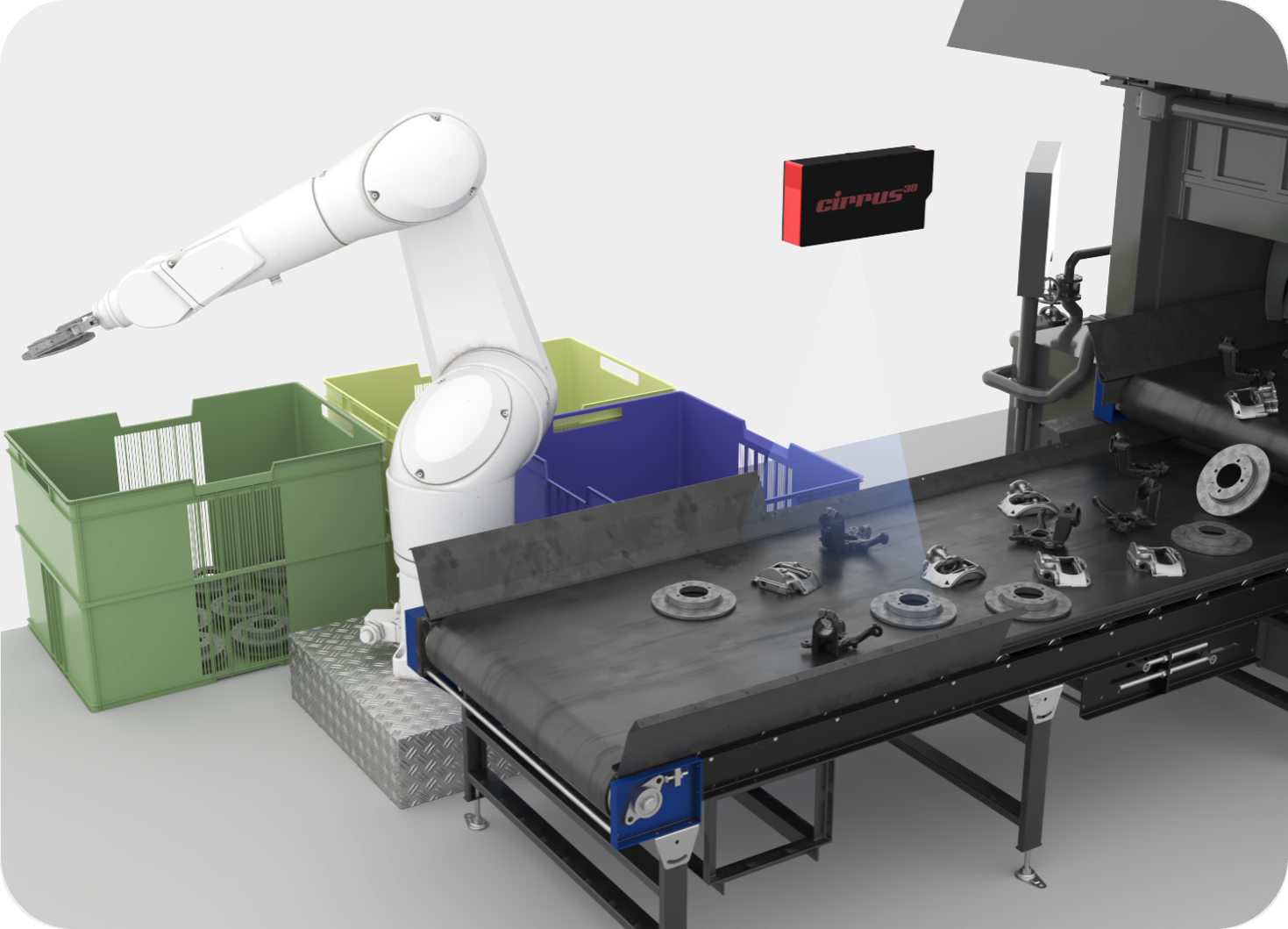

Robot guidance

For cost-effective automation of precise robotic operations

Bin picking

For cost-effective automation of production line loading with parts arranged in bulk, semi-rowed

or in rows.

Optical sorting

To eliminate intruders and non-conforming items, even on your high-speed conveyors

Parts identification

To efficiently identify and locate a part by its geometry among several hundred listed part

numbers

Inspection and dimensional control

For real-time control of parts on production lines