Robot

guidance

With agility and precision

Robot guidance?

- Guarantees approach accuracy, taking into account variations in part shape and position.

- Defines an optimal robot trajectory, taking into account its own singularities and possible collisions within the working environment.

- Makes it possible to work with or without the CAD model of the part, to meet a wide range of applications in the general and food industries.

The complete process

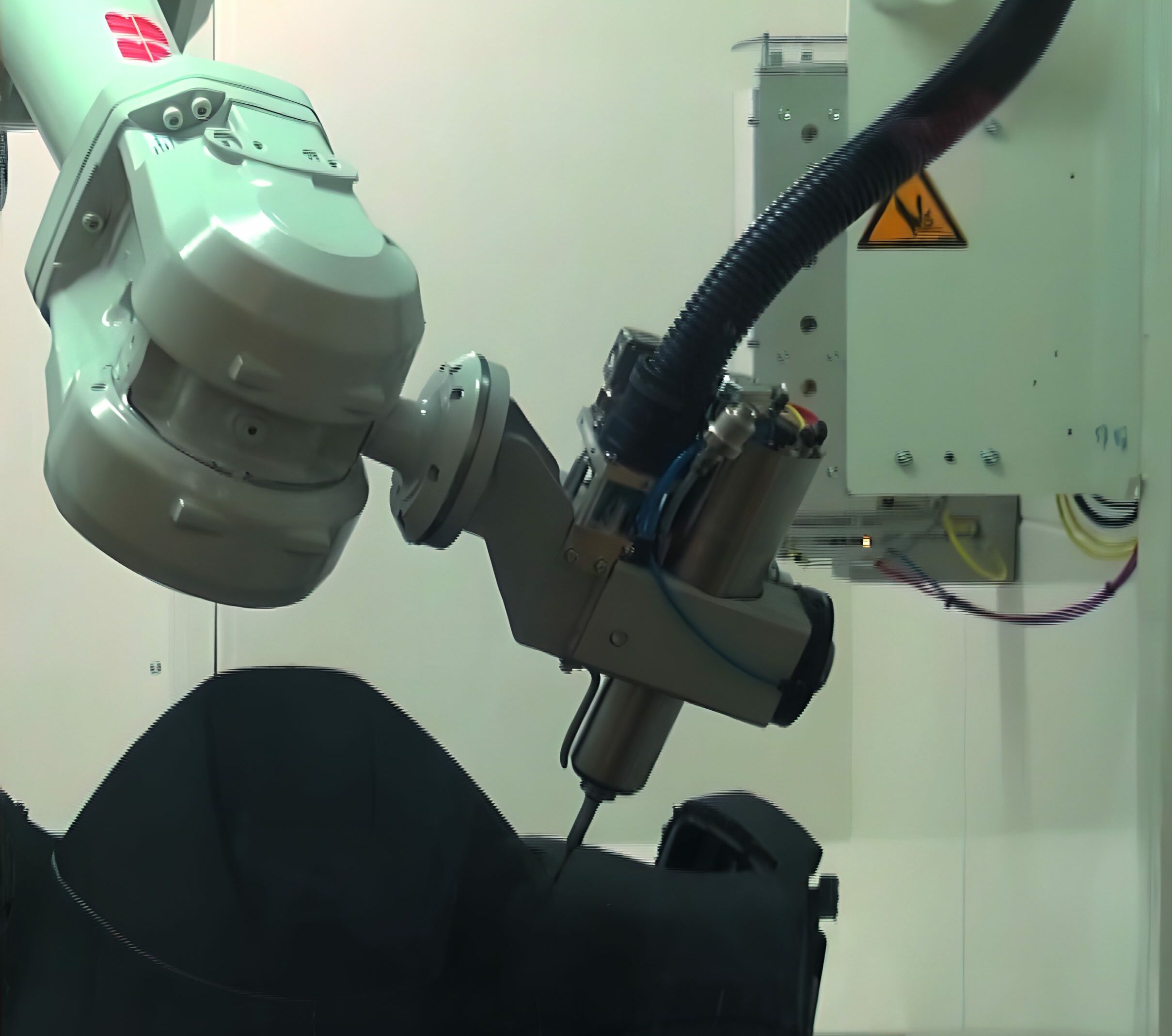

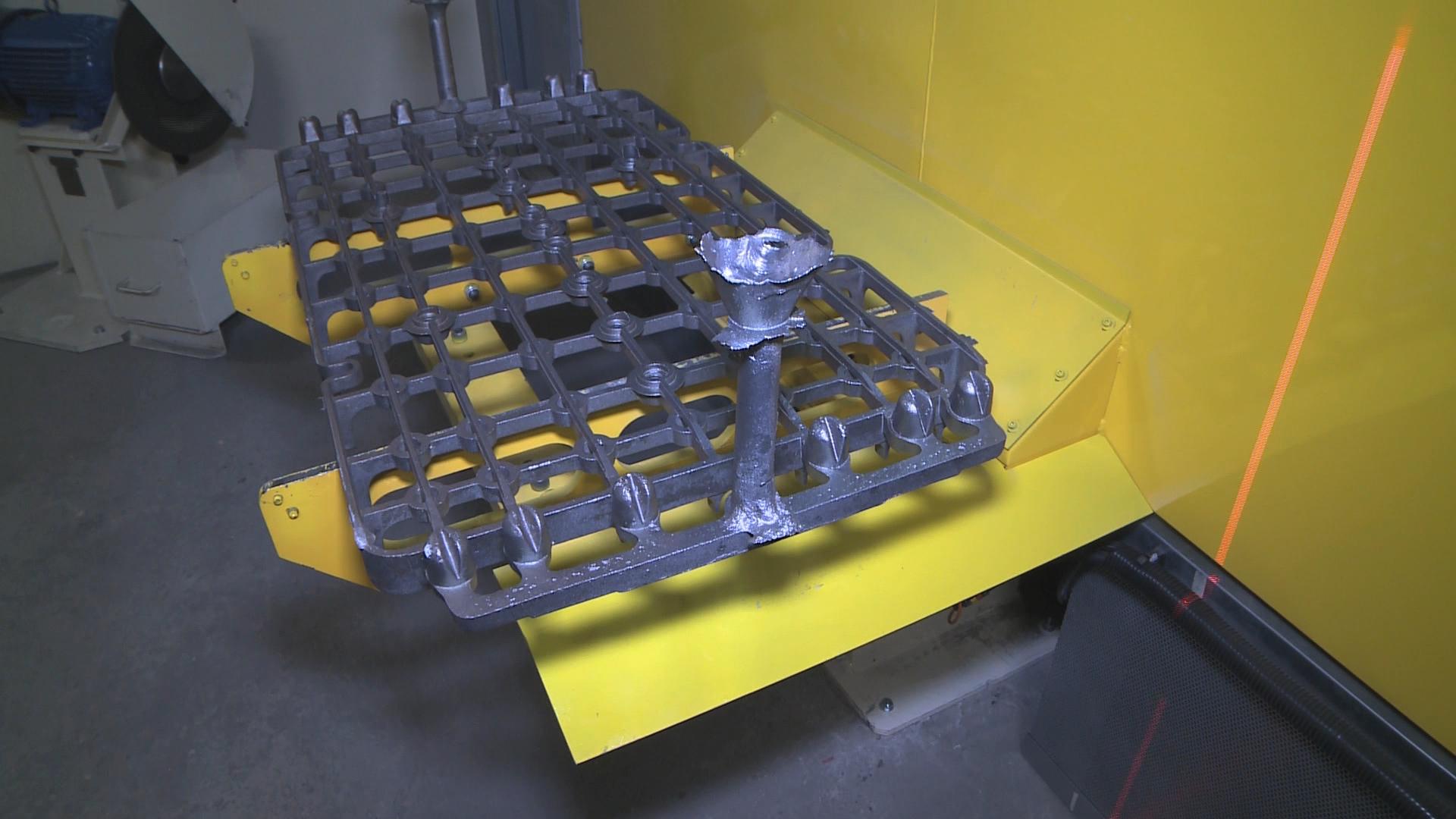

Step 1: DIGITIZING

From real to virtual

The Cirrus3D camera digitizes the actual work scene in the form of a 3D cloud of points. The sensor uses stereovision technology for data acquisition, ensuring the quality of the information contained in the scan for maximum performance in scanning results. The user can graphically define the parameters of the working scene: working volume, density of points contained in the cloud of points.

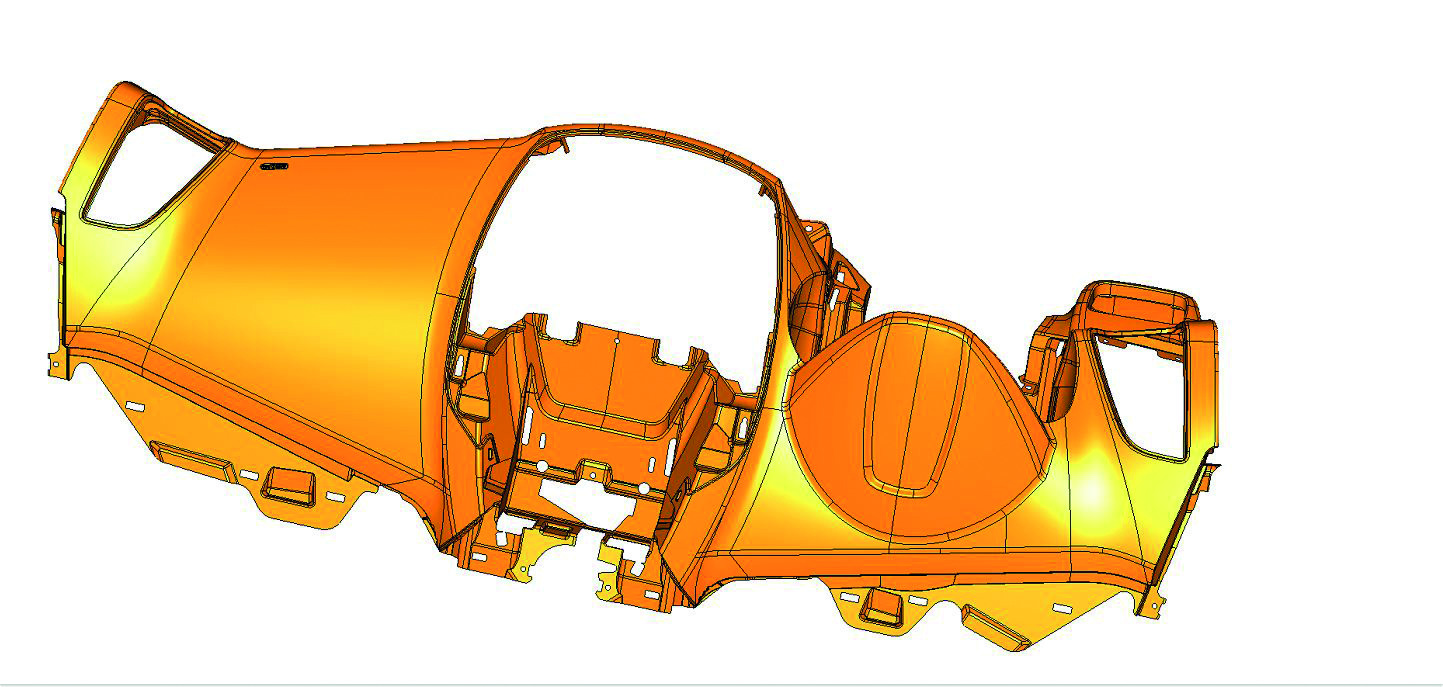

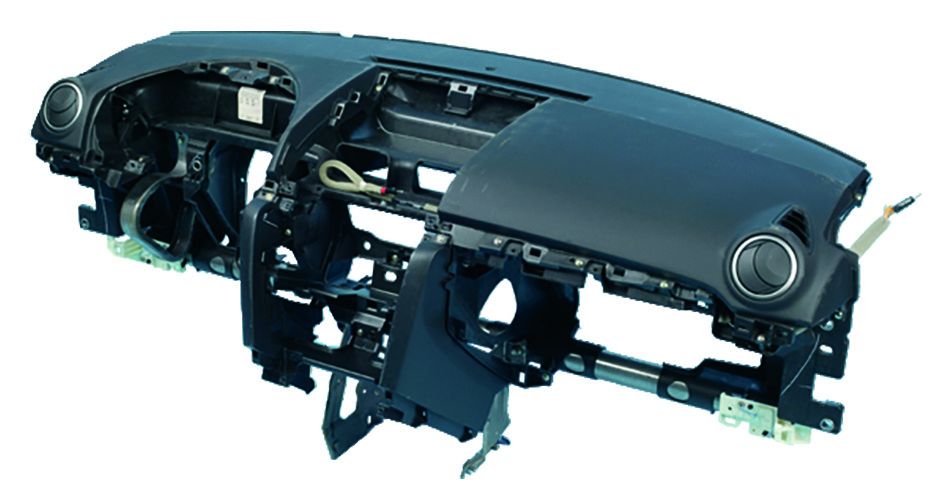

Step 2: LOCALIZATION

Localization and alignment

Combining the cloud of points with the CAD model of the part helps to compensate for positioning errors and local shape defects. The use of the latest generation of AI-based algorithms optimizes the automatic recognition of random-shaped objects without any specific programming.

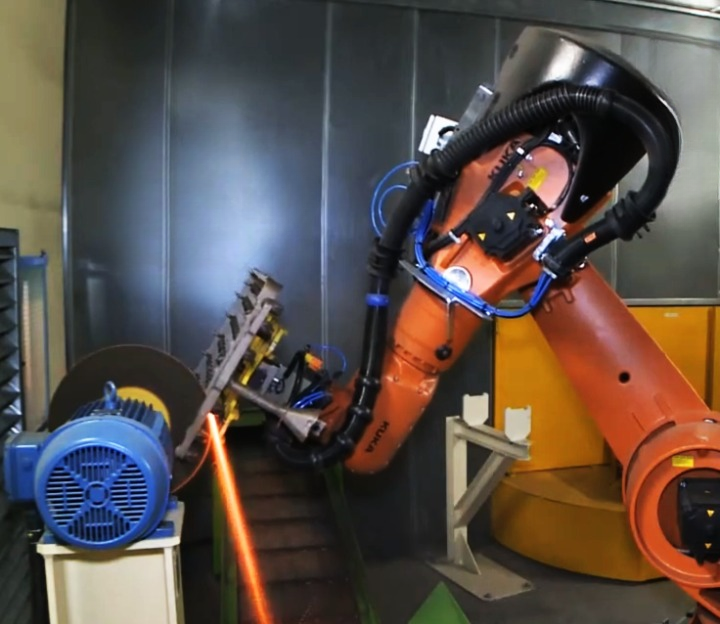

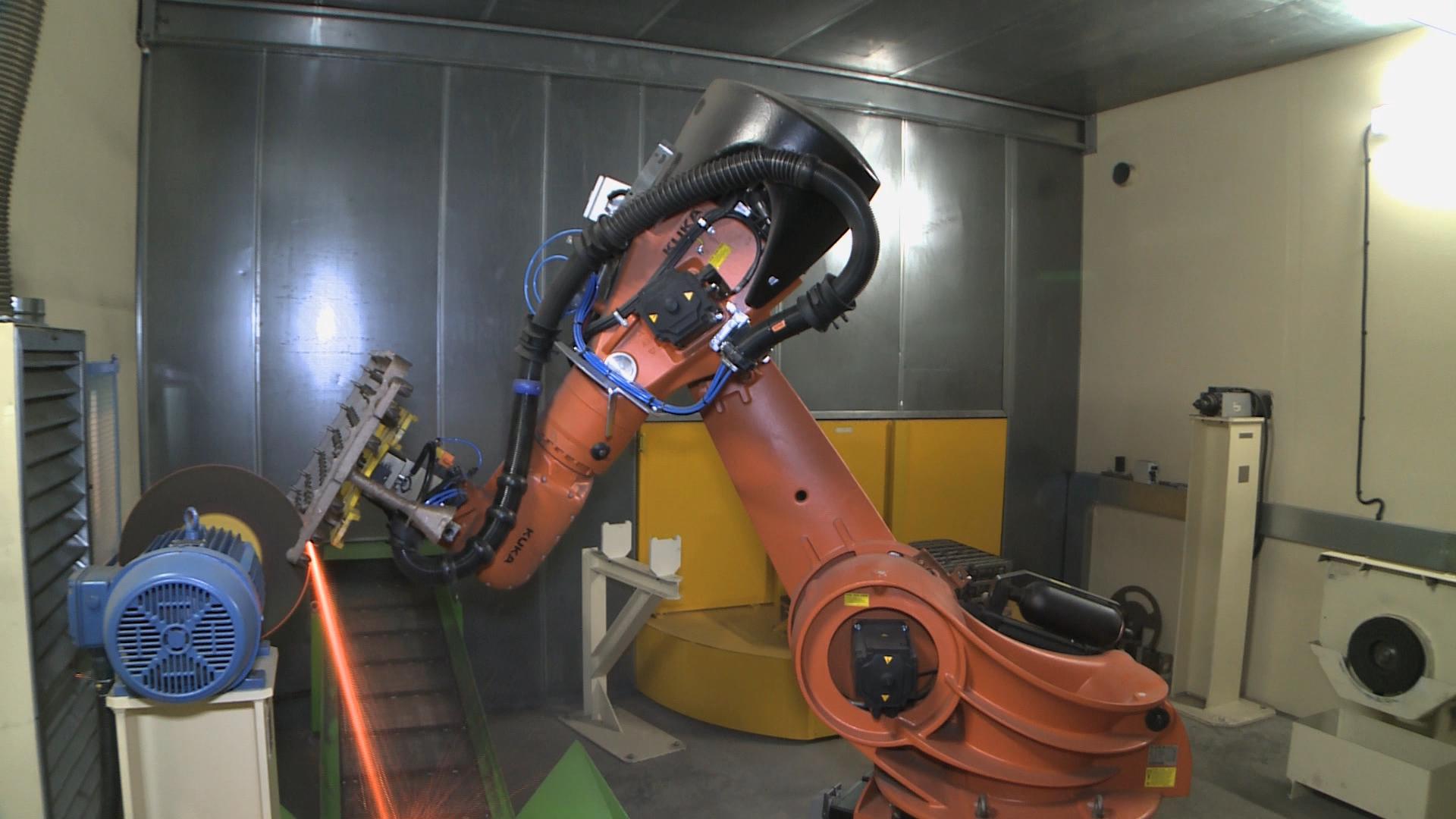

Step 3: ROBOT GUIDANCE

Robot path generation

The robot cell receives trajectory corrections so that the tool follows the skin of the part as closely as possible.

The image processing software takes charge of calculating the optimal robot trajectory, whatever its make. It transmits the angular positions of each axis to the robot controller, taking into account any singularities.

As a result, robot applications are easier to develop, and integration time is considerably reduced. In addition, collision management is better understood, enabling the robot to access the part in complete safety.

In the end, this simpler and shorter integration, combined with a greater productivity, also guarantees a faster ROI.

Application examples

Why

Since the first-generation Cirrus3D camera was launched in 2015, Visionerf has constantly improved its products to provide customers with a high-end scanner capable of operating in the harshest environments, such as foundries or dusty, humid environments.

The unique design of this camera, based on the principle of high-resolution stereoscopy, enables very small elements to be viewed with the utmost precision in the shortest possible time. Combined with powerful structured light, the quality of information remains constant across a wide range of materials. From black to high-gloss, measurement reliability remains flawless.

The choice of top-of-the-range components contributes greatly to the robustness and reliability of our products. Today, our cameras are used in all sectors of activity, for precise handling of parts of all sizes (screws, mechanical bodywork parts), for robot guidance in high-volume applications (from automatic detection of potential gas leaks on refrigerators to automatic changeover of drilling tools on giant tunnel boring machines), and for monitoring and inspecting objects directly on production lines.